0555-6768298

0555-6768298

0555-6768298

0555-6768298

Если у вас есть вопросы или предложения, пожалуйста, оставьте нам сообщение, мы ответим вам, как только сможем!

Связаться с нами

Преимущества Производство за два или три хода Уменьшение следов благодаря подпружиненному прижимному устройству Активные компоненты закалены Высокая повторяемость благодаря встроенному упору Функциональная проверка и регулировка посредством испытательных изгибов - с вашими образцами Подходит для материалов толщиной минимум до 4,0 мм внутренний Ø: 2,5 мм x толщина материала для стали и алюминия 3,0 мм x толщина материала для нержавеющей стали

Пресс-тормозные штампы без царапин, лучше всего положить пленку на поверхность заготовки при сгибании. и мы порекомендуем вам подходящий размер матрицы Roll-V в зависимости от пластины, которую вы сгибаете.

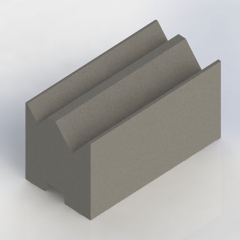

Регулируемые плашки с регулировочными шайбами Регулируемые нижние плашки можно считать одним из самых универсальных дополнений к листогибочному прессу. С этим типом инструмента отверстия могут быть расположены от 6,35 мм до 381 мм. Для создания необходимого отверстия предусмотрены распорки. Прорези с прорезями позволяют легко снимать, чтобы изменить отверстие матрицы. Когда они не используются, распорки располагаются по бокам блока матрицы. Эти штампы могут быть цельными или секционными для удобства обращения.

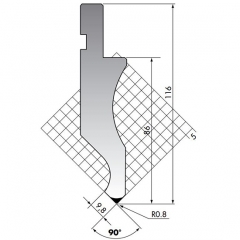

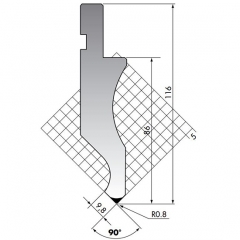

Прямой размер лезвия: 835*146*26 мм, 90 градусов. материал 42CrMo4, твердость HRC47+/-3

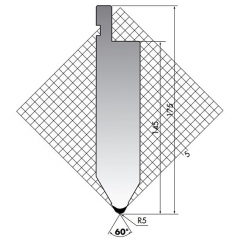

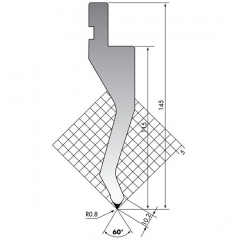

Прямой размер лезвия: 835*175*40 мм, 60 градусов. материал 42CrMo4, твердость HRC47+/-3

Прямой размер лезвия: 835*146*26 мм, 90 градусов. материал 42CrMo4, твердость HRC47+/-3

Прямой размер лезвия: 835*145*32 мм, 60 градусов. материал 42CrMo4, твердость HRC47+/-3

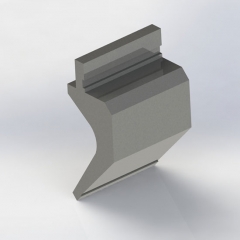

Размер перфоратора «гусиная шея»: 835*197*92 мм, 88 градусов. материал 42CrMo4, твердость HRC47+/-3. и высота 197мм, ширина 92мм. можно сделать по желанию заказчика.

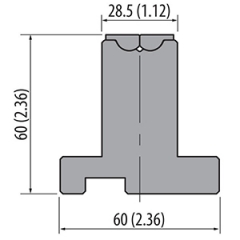

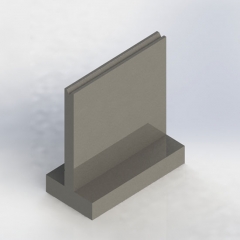

Размер матрицы телевизора: 835*120*60 мм, V12, 30 градусов. материал 42CrMo4, твердость HRC52-58. и V6,V8,V10,V16,V20,V25 могут быть изготовлены по запросу заказчика.

Самоцентрирующиеся штампы 2V, размер 835*46*50 мм, 88 градусов, вес 17 кг. Мы можем изготовить V5-V9, V8-V12, V12-V20, V16-V25 и другие V-образные отверстия в соответствии с толщиной изгиба.

В традиционных процессах гибки формы часто оставляют вмятины или царапины на поверхности листового металла. Эта проблема особенно заметна при обработке зеркальных панелей из нержавеющей стали, алюминиевых листов или декоративных элементов, что значительно ухудшает внешний вид и общую ценность изделия, а иногда даже приводит к доработке или браку. В связи с растущими требованиями к качеству поверхности в производстве появились инструменты для гибки, предотвращающие появление царапин.

Виды Инструмент для листогибочного пресса без следов :

Инструменты для гибки, предотвращающие появление царапин и вмятин, имеют специальную конструкцию или изготовлены из материалов, предотвращающих их образование. К распространенным типам относятся:

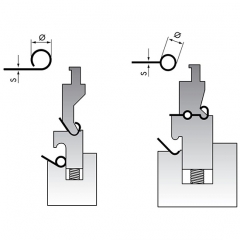

Инструменты с шариковыми подшипниками, предотвращающие появление царапин: они поддерживают листовой металл с помощью шариковых подшипников, значительно снижая трение, эффективно предотвращая появление царапин и делая процесс гибки более плавным.

Инструменты с механизмом переворачивания, предотвращающим появление царапин: опорная поверхность может переворачиваться в зависимости от угла изгиба, избегая повреждения поверхности. Этот гибкий механизм переворачивания обеспечивает равномерную поддержку листового металла на протяжении всего процесса изгиба, предотвращая локальные вмятины.

Инструменты с полиуретановыми накладками, защищающими листовой металл: благодаря гибким накладкам, предохраняющим листовой металл, эти инструменты особенно подходят для высокоточной обработки листового металла с высоким качеством поверхности.

Преимущества инструментов для гибки, не оставляющих царапин:

По сравнению с традиционными инструментами, формы, не оставляющие царапин, обладают явными преимуществами в обработке листового металла:

Защитите поверхности листового металла: предотвратите вмятины и царапины, обеспечив высокое качество внешнего вида.

Снижение материальных затрат: минимизация доработок и полировки, повышение эффективности производства. .

Высокая адаптивность: подходит для различных материалов и толщин, удовлетворяя разнообразным технологическим требованиям.

Увеличение срока службы пресс-формы: шарикоподшипниковые или опорные конструкции уменьшают износ, продлевая срок службы инструмента.

Применимые материалы и отрасли промышленности:

Инструменты для гибки без образования царапин широко используются для обработки металлических листов, требующих чрезвычайно высокого качества поверхности, включая зеркальные панели из нержавеющей стали, алюминиевые листы, оцинкованные листы и декоративные панели с покрытием или окраской. Они применяются в различных высокотехнологичных отраслях промышленности, таких как:

Декоративное оформление лифтов и зданий: панели лифтов, металлические навесные стены и различные декоративные элементы из нержавеющей стали.

Кухонная утварь и бытовая техника: для изготовления корпусов посуды, холодильников, стиральных машин и т. д., обеспечивающих гладкие и привлекательные поверхности.

Медицинское и прецизионное оборудование: для деталей из листового металла медицинских приборов, контрольно-измерительных приборов и других изделий, требующих строгой целостности поверхности.

Высококачественная листовая металлическая продукция, изготавливаемая на заказ: например, компоненты для аэрокосмической отрасли или элементы роскошного интерьера, где детализация поверхности и качество имеют чрезвычайно важное значение.

В целом, инструменты для гибки без царапин не только улучшают качество поверхности изделий, но и помогают компаниям, занимающимся обработкой листового металла, снижать производственные затраты и повышать эффективность. В последние годы компания Golin Tooling идет в ногу со временем в области гибки без царапин, разрабатывая и выпуская множество таких инструментов, которые продаются в Европе, Южной Америке и некоторых странах Ближнего Востока и получают неизменно высокую оценку от клиентов. В будущем спрос на гибку без царапин в высокотехнологичном производстве будет продолжать расти, и Golin продолжит предоставлять профессиональные и эффективные инструментальные решения клиентам по всему миру.

онлайн

онлайн 0555-6768298

0555-6768298 0555-6769126

0555-6769126 sales2@cngolin.cn

sales2@cngolin.cn +86 18251802252

+86 18251802252